BioNova Waste Solution transform organic waste to Biomass within 24h.

BioNova - Welcome!

BioNova Sweden was founded in 1993 by the inventor and developer of the BioNova rapid digester technology (RDT) system, Lars Ebertsson.BioNova Sweden manufactures and sells a range of world-recognised RDT systems that convert food and green organic waste (FOGO) into a nutrient-rich bio-fertiliser or bioenergy feedstock.BioNova Pacific Pty Ltd was formed in 2022 to bring the full range of BioNova RDT solutions to Australia , New Zealand and Oceania by 3 Australian-based partners and Lars Ebertsson all experienced in biomass waste conversion technologies.BioNova RDT systems rapidly transform FOGO waste into a valuable resource within a 24-hour period and reduce waste weight and volume by up to 75-85% using best practice aerobic technology solutions.BioNova RDT systems are suitable for businesses or organisations producing 35 tonnes of FOGO (Food Organics, Green Organics) per annum to large-scale entities that process 25,000 tonnes or more of FOGO per annum.

The BioNova process not only minimises transport & disposal costs but provides a range of direct and indirect benefits to your business or organisation:

Substantial reduction in the volume of your FOGO waste

BioNova Sweden’s RDT advanced enzyme system enables a 24 hour processing cycle.

Digestate can be employed on or near the installation site.

The process is Pathogen and odour-free

The BioNova RDT system is waterless

Low power inputs required to transform waste into a valuable resource

Creates a valuable biomass digestate to improve soil productivity and plant growth

Net carbon emissions reduction by capturing carbon and avoided landfill

Produces a valuable bio-fertiliser

Digestate can be pelletised to create a valuable bio-energy feedstock

NOTE: - Ask about our obligation-free organic waste audit for your business or organisation.

Frequently Asked Questions

Is BioNova RDT the same as the BioNova technology?

Yes, it is the same technology, just renamed to reflect the ongoing evolution of the core principles of continuous aerobic transformation of BioNova technology systems and applied enzymes.

Is it a continuous or batch process?

BioNova RDT is a continuously fed process usually manually feeded for models up to the C10 range with continuous process loading technologies employed at larger waste feedstock volumes. (above the C20 range)

Is it an automated process?

Our systems typically use PLC controls, instruments and protection systems that allow push button start/stop and extended periods of unattended operation. Operators can view and remotely control the systems via an internet connection, if desired.

Is it mobile?

The smaller models can be configured as mobile or relocatable systems.

What models do you have?

Please refer to Digester Range

What materials can be used?

Organic material such as:

• Vegetables & Fruits

• Bread/Bakery

• Coffee/Tea

• Meat and fish remains

• Eggs/Eggshells

• Flowers

• Shredded Paper and Cardboard

• Sewage Sludge

For more information please refer to Feedstock Requirements.

Where do you manufacture and sell the equipment?

The equipment is designed in Sweden to European standards and manufactured in Poland and Australia and is sold world-wide. Local certifications (eg. CE marking) are performed on a project by project basis.

The Process

Read more about the process on the pages below.

Waste Reduction

BioNova digesters reduce the volume and mass by around 70%.

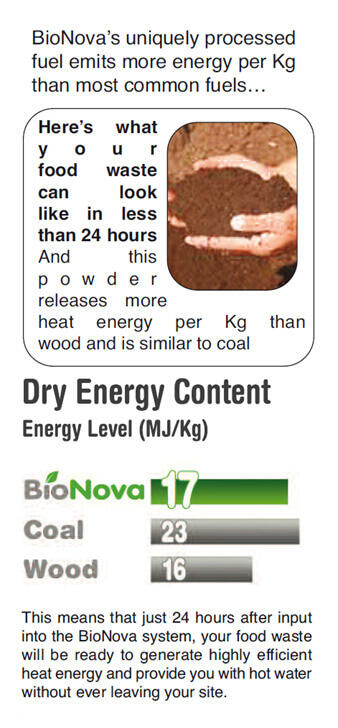

Then BioNova ‘Digestate’ use: as a Soil enhancer or as a Biomass Fuel or AD Feed Stock.

Read more about the process on the pages below.

Food waste to fertilizer

Read more about the process on the pages below.

Food waste to energy

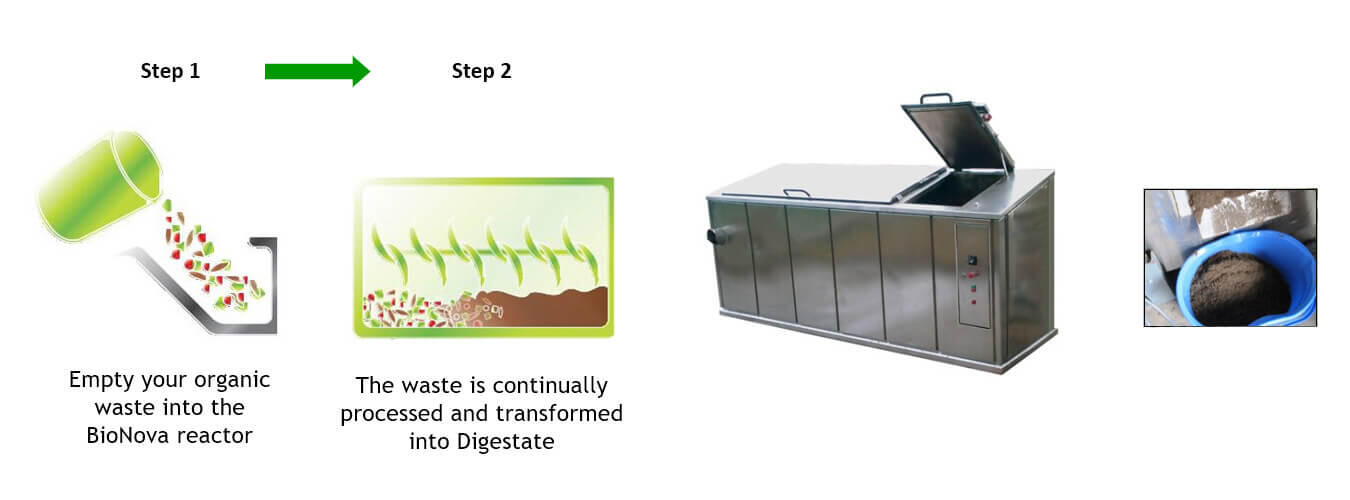

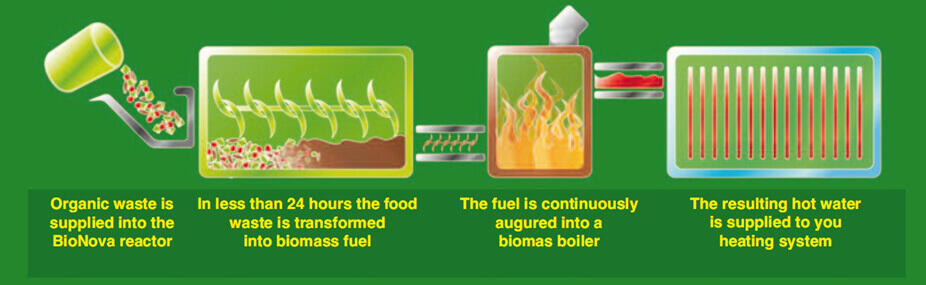

Steps

Place your organic waste material into the BioNova Digester.

The Food waste will then pass through the aerobic digestion process and be transformed into a burnable biomass fuel.

The Fuel is then continuously burned in a specific biomass boiler on its own or with co-fuelling.

The Resulting heat is supplied as air or water for your heating system or can be converted to cooling.

Read more about the process on the pages below.

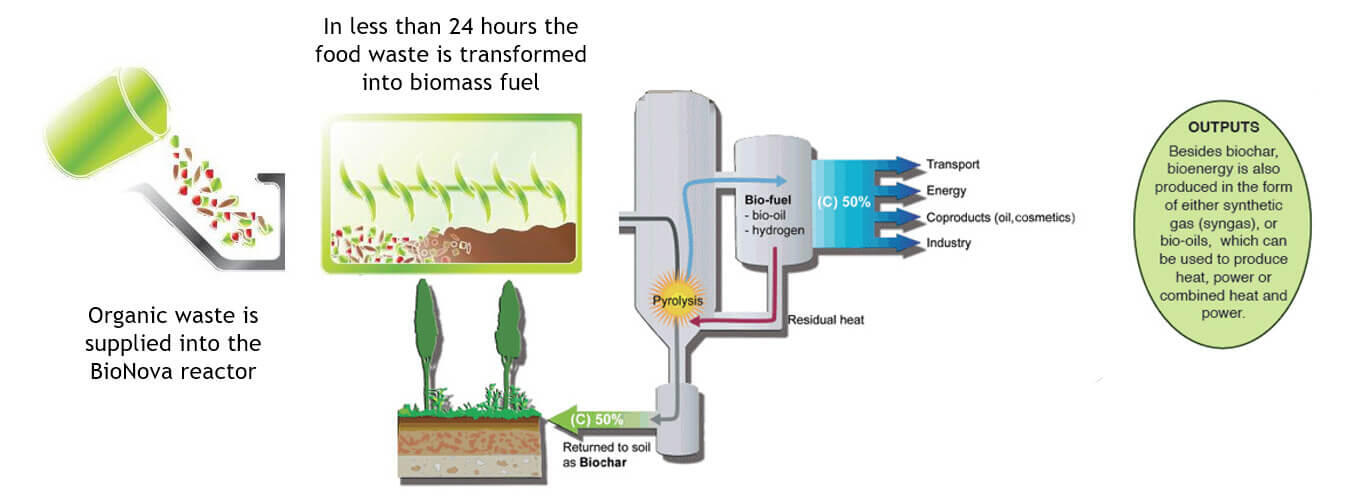

Biomass to Pyrolysis

The BioNova system will continously process organic waste into a high energy efficient fuel typically within 24 hour period and there is ongoing testing and research to reduce this further.

Read more about the process on the pages below.

Benefits

The BioNova System will make you better off in the following ways:

Eliminates your waste costs.

Reduces your existing fuel bill.

Advantages of BioNova System:

Reduces weight and volume.

End product used as a fertilizer.

End product can create a biofuel for hot water/air or cold water/air.

Greener business

With a BioNova system you are promoting yourself as a greener environmentally friendly business, while reducing your Co2 emissions and improving your carbon footprint.

Read more about the process on the pages below.

Products

Manufacturing complies with European Standards and the digestate production complies with National EPA and International Standards

Digesters Range S - XL

Feedstock particle size, moisture content and waste content all have an impact on suitability for use in a BioNova RDT system. We have used BBB in the particle size examples below, however the same sizing principles apply to other feedstocks.

Small C2

Medium C5

Large C20

Large C50

| Performance Data – Food Wastes | C1 | C2 | C3 | C5 | C10 | C20 | C50 |

|---|---|---|---|---|---|---|---|

| Input Capacity (Ltrs/Week) | 1,000 | 2,000 | 3,000 | 5,000 | 10,000 | 20,000 | 50,000 |

| Input Capacity (Kgs/Week) | 700 | 1,400 | 2,200 | 3,500 | 7,000 | 14,000 | 35,000 |

| Annual Tonnage Input (Tonnes) | 37 | 73 | 110 | 182 | 364 | 728 | 1,820 |

| Annual Digestate Output (Tonnes) | 9 | 18 | 27 | 45 | 90 | 180 | 546 |

| Annual Saving in Disposal (Tonnes) | 28 | 55 | 83 | 137 | 274 | 584 | 1,274 |

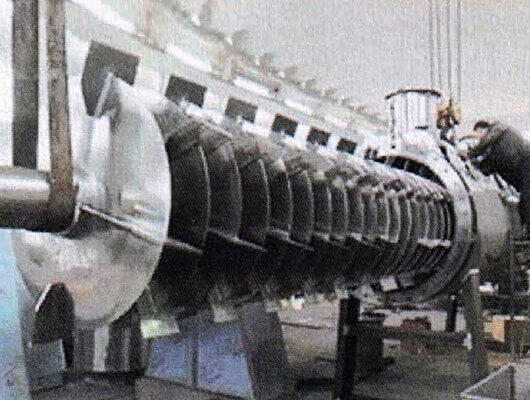

Digesters Range XL - 5XL

Extra large Digesters for Waste Management, Councils, Landfill, Food Industries.Capacity from 5.000 tns/year up to 25.000 tns/year with possibilities to expand with side by side position.XL: 5.000MT

2XL: 10.000MT

3XL: 15.000MT

4XL: 20.000MT

5XL: 25.000MT

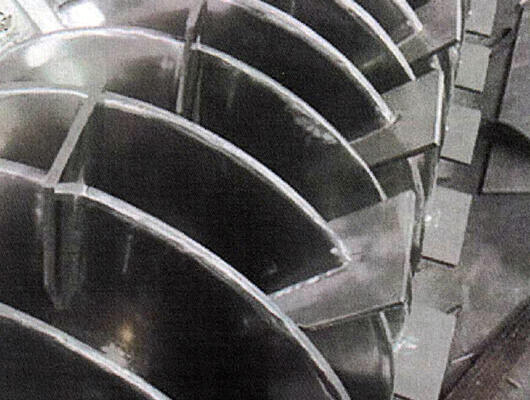

Disc Dryers

Disc Dryers for sewage, food industy or any other organic sludge or Biomass.Capacity from 5.000 tns/year up to 50.000 tns/year with possibilities to expand with side by side position.Images show discs inside the drying chamber.BioNova Range now includes BioNova Disc Dryers specifically for…

Sewage sludge

Food industry sludge

Other sludge from organic material.

Could be used as biomass for Power plants or for Pyrolysis

Initial Scope form

Thank you for your interest in BioNova RDT systems.The selection of a BioNova RDT system depends on customer specific requirements. To enable us to provide an initial evaluation about how a BioNova RDT solution will suit your needs, please complete this form.BioNova Pacific may ask for additional information about your application to further scope the project.